Project F – Room Temperature Aerosol Deposition of Lead-Free Ferroelectric Films for Energy Conversion Systems

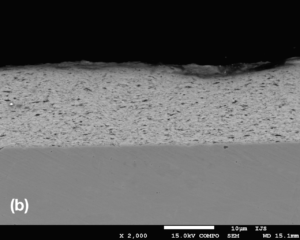

The focus of this project is the investigation of lead-free ferroelectrics films for energy conversion applications using aerosol deposition (AD). During deposition, micron-sized particles are accelerated through a nozzle by a carrier gas into a vacuum chamber. The particles impact a substrate, breaking apart and forming a dense (>96 %) ceramic film at room temperature with an exceptionally high deposition rate. Because AD is a room temperature process, deposition of metallic, ceramic, semi-conductor, glass, or plastic particles on various substrates is possible. This is not achievable with other film deposition techniques requiring high temperature densification. Multi-layer composite structures consisting of alternating layers of different materials (2-2 connectivity) (Figure 1a) or mixed composite structures (0-3 connectivity) as well as porous films structures can also be produced, which could be used to optimize electromechanical properties or build-in additional functionalities.

![]()

Figure 1. (a) BaTiO3/SrTiO3 composite on Pt-electroded Si-wafer and a (b) porous BaTiO3 film on a steel substrate.

The primary research goal is the improved understanding of the deposition of lead-free ferroelectric films for energy conversion applications using AD. Methods to thermally, chemically, and microstructurally tune the residual stress in the films will also be investigated, in addition to enhancement in electromechanical coupling using ceramic/ceramic composites and novel 3D film structures.

Principal Investigators

|

Prof. Dr. Kyle G. Webber Institute of Glass and Ceramics Materials Science Department Friedrich-Alexander-Universität Erlangen-Nürnberg kyle.g.webber@fau.de |

|

Prof. Dr. Ken-ichi Kakimoto Life Science and Applied Chemistry Department Frontier Research Institute for Materials Science Nagoya Institute of Technology kakimoto.kenichi@nitech.ac.jp |

Doctoral Researchers

|

M.Sc. Michel Kuhfuß Institute of Glass and Ceramics Materials Science Department Friedrich-Alexander-Universität Erlangen-Nürnberg michel.kuhfuss@fau.de |

|

M.Sc. Takumi Nozaki Nagoya Institute of Technology |

Associated Researchers

Dr. Neamul Hayet Khansur (FAU): neamul.khansur@fau.de

Dr. Xi Shi (FAU): xi.shi@fau.de

Dr. Alexander Martin (NITech): martin.alexander@nitech.ac.jp

Dr. Daisuke Urushihara (NITech)

Publications Project F

2024

- , , , , , , , , , , , , , , :

The role of Ca/Zr ratio on the local structure and phase transitions in lead-free (Ba,Ca)(Zr,Ti)O3

In: Journal of the European Ceramic Society (2024)

ISSN: 0955-2219

DOI: 10.1016/j.jeurceramsoc.2024.03.003

2022

- , , , , , , , , , , , :

Temperature-dependent dielectric anomalies in powder aerosol deposited ferroelectric ceramic films

In: Journal of Materiomics 8 (2022), S. 1239-1250

ISSN: 2352-8478

DOI: 10.1016/j.jmat.2022.05.001 - , , , , , , , , , , :

Room temperature deposition of freestanding BaTiO3 films: temperature-induced irreversible structural and chemical relaxation

In: Journal of Materials Science (2022)

ISSN: 0022-2461

DOI: 10.1007/s10853-022-07467-3 - , , , , , , :

Defect modulated dielectric properties in powder aerosol deposited ceramic thick films

In: Ceramics International 48 (2022), S. 33082-33091

ISSN: 0272-8842

DOI: 10.1016/j.ceramint.2022.07.241 - , , , , :

Investigating the importance of strain-coupling in lead-free 2-2 relaxor/ferroelectric composites with digital image correlation

In: Smart Materials & Structures 31 (2022)

ISSN: 0964-1726

DOI: 10.1088/1361-665X/ac6fa0 - , , , , :

Temperature-dependent ferroelastic behaviour of antiferroelectric AgNbO3

In: Acta Materialia 232 (2022)

ISSN: 1359-6454

DOI: 10.1016/j.actamat.2022.117931 - , , , , , , , :

Electromechanical properties of paper-derived potassium sodium niobate piezoelectric ceramics

In: Journal of the American Ceramic Society (2022)

ISSN: 0002-7820

DOI: 10.1111/jace.18655 - , , , , , , , , , :

Temperature-induced changes of the electrical and mechanical properties of aerosol-deposited BaTiO3 thick films for energy storage applications

In: Journal of the American Ceramic Society (2022)

ISSN: 0002-7820

DOI: 10.1111/jace.18377

2021

- , , , , , , , , :

Enhanced Electromechanical Response and Thermal Stability of 0.93(Na1/2Bi1/2)TiO3-0.07BaTiO3 Through Aerosol Deposition of Base Metal Electrodes

In: Advanced Materials Interfaces (2021)

ISSN: 2196-7350

DOI: 10.1002/admi.202100309 - , , , , , :

Stress- And frequency-dependent properties of relaxor-like sodium bismuth titanate

In: Physical Review B 103 (2021), Art.Nr.: 094113

ISSN: 0163-1829

DOI: 10.1103/PhysRevB.103.094113 - , , , , , , , , , , , :

Energy-storage-efficient 0.9Pb(Mg1/3Nb2/3)O3–0.1PbTiO3 thick films integrated directly onto stainless steel

In: Acta Materialia 221 (2021), Art.Nr.: 117403

ISSN: 1359-6454

DOI: 10.1016/j.actamat.2021.117403 - , , , , , , , , , :

Characterization of Aerosol Deposited Cesium Lead Tribromide Perovskite Films on Interdigited ITO Electrodes

In: Advanced Electronic Materials (2021)

ISSN: 2199-160X

DOI: 10.1002/aelm.202001165

2020

- , , , , , :

Determining the local pressure during aerosol deposition using glass memory

In: Journal of the American Ceramic Society 103 (2020), S. 2443-2452

ISSN: 0002-7820

DOI: 10.1111/jace.16947 - , , , , , :

High temperature piezoelectric response of polycrystalline Li-doped (K,Na)NbO3 ceramics under compressive stress

In: Journal of Applied Physics 127 (2020), Art.Nr.: 114101

ISSN: 0021-8979

DOI: 10.1063/1.5134554 - , , , , , , , , , , :

Effect of Ligand Treatment on the Tuning of Infrared Plasmonic Indium Tin Oxide Nanocrystal Electrochromic Devices

In: Advanced Engineering Materials (2020)

ISSN: 1438-1656

DOI: 10.1002/adem.202000112